-

TOP

- Business Overview

- Logistics Strategy

Logistics Strategy

As part of Yamazen's Company-wide strategy, we are promoting the Logistics Strategy to address the material issue of realizing sustainable procurement and supply. As a specialized trading company responsible for streamlining the supply chain, improving and expanding logistical functions is a priority management issue. Amid urgent challenges such as driver shortages and environmental impact reduction, we have initiated efforts to enhance logistics efficiency and service capabilities, with a focus on establishing the next-generation logistics system, including joint delivery.

Basic Policy

Improved Efficiency of Logistics Business and Contribution to Sustainability

The role of logistics as well as related efficiency demands are increasing dramatically, driven by rapid changes in consumption behavior, such as e-commerce and delivery services, rising fuel and labor costs, and advances in IT, notably AI. Even in the logistics business, there is a marked trend toward automation and labor-saving in areas such as material handling and delivery instructions using IoT, from warehouse work to transportation and delivery. In addition, the rethinking of long-distance transportation methods due to restrictions on the working hours of drivers, the push to reduce CO2 emissions related to warehouse work and transportation and delivery, as well as BCP measures for disasters, are fueling a strong need to build a sustainable logistics network. Based on these medium- to long-term trends, the Group has formulated a three-phase, nine-year logistics strategy by backcasting from the Corporate Vision for 2030, and is actively investing management resources in promoting this strategy.

Vision and overall strategy framework

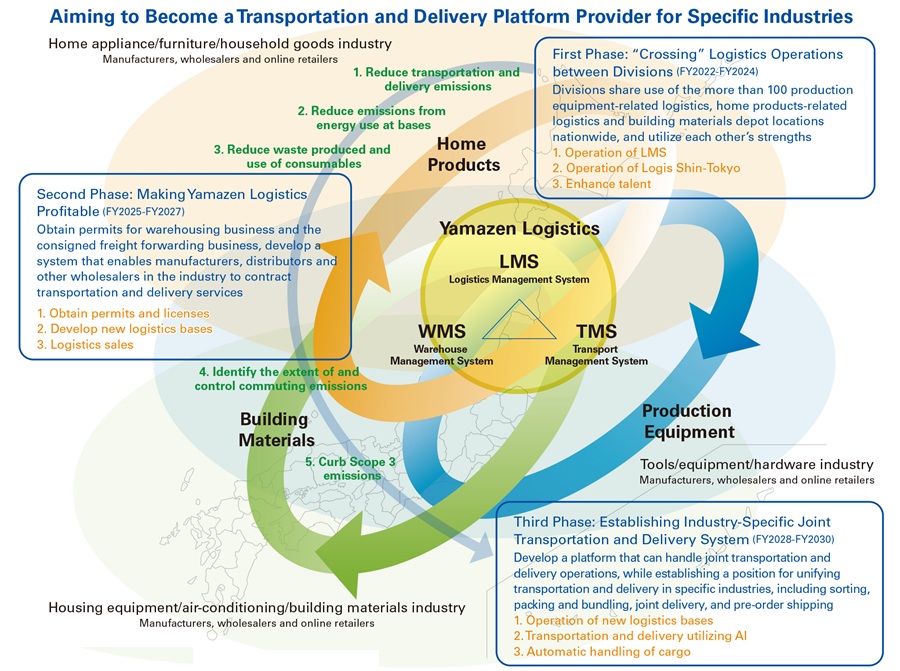

Yamazen's Vision for its logistics strategy is to become a transportation and delivery platform provider for specific industries, unifying various sectors where we hold strengths across the board. Aiming for realization by 2030, we have outlined our logistics strategy across three phases. The first phase initiative, “Crossing” Logistics operations, and the second-phase goal, Making Yamazen Logistics profitable, both serve as preparatory steps. They utilize logistics hubs and transportation networks to the fullest as we work toward establishing a comprehensive scheme.

First Phase: “Crossing” Logistics operations between divisions (2022–2024)

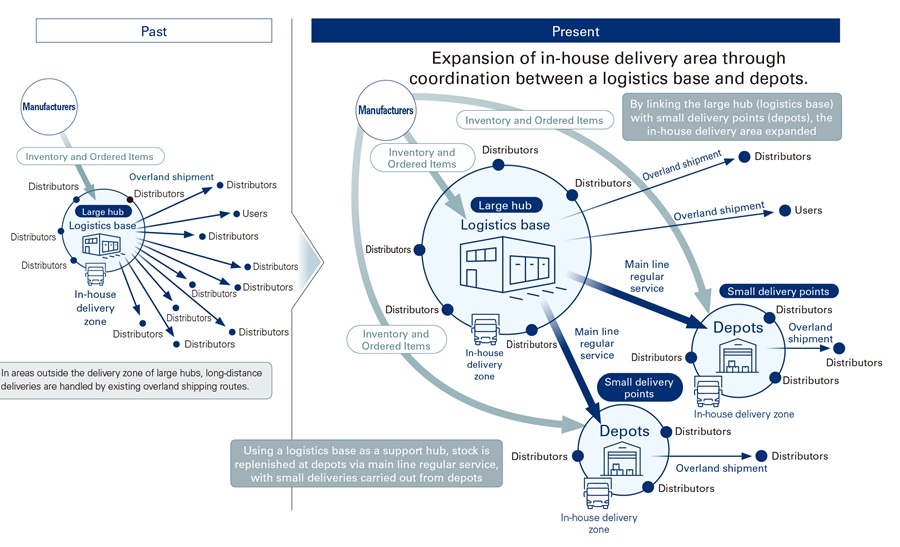

First Phase is progressing smoothly. Through shared cross-divisional use of all 122 production equipment-related logistics, home products-related logistics, and building materials depot locations nationwide, we are advancing efforts to leverage the strengths of each business division. The sharing of depots began in Okayama and has since expanded to Kanazawa, Sendai, Sapporo and Shizuoka. We have achieved shorter delivery distances and improved service levels, enabling us to cover “areas” rather than just “points.” We will continue to promote further “Crossing” of divisions, while also focusing on logistics digital transformation (DX) and reducing environmental impact.

Highlights 01 Reducing Logistics Costs (Results) and Enhancing Service Levels by Introducing LMS and WMS

Yamazen has been advancing the implementation of its logistics management system (LMS) and warehouse management system (WMS), with seven sties having completed installation as of March 2024. At Logis Tokyo (Kitamoto City), picking productivity increased by approximately 2.3 times compared to before relocation, while shipping errors were reduced by about one-third. Combined with the effect of material handling equipment installation, in-warehouse staffing was reduced by approximately 25%. At Logis Ashikaga (Ashikaga City), appropriate packaging calculations reduced the number of packages by about 30%, leading to reduced shipping costs. Standardization of tasks enabled faster skill acquisition for new workers. Service improvements were also achieved, such as attaching packing details to allow contents to be identified before unpacking. We plan to implement these systems across all warehouses, aiming to enhance productivity and control costs.

Highlights 02 Logis Osaka Commences Full Operations in January 2025

Logis Osaka (Higashiosaka City), a vital logistics hub that supports the manufacturing industry in western Japan, commenced full operations in January 2025. To promote automation of in-warehouse logistics, we have introduced cutting-edge systems that do not require employee mastery, such as automated warehouses, projection mapping, and autonomous mobile robots (AMRs). These systems streamline the entire process from product storage to shipping to allow for work with fewer human resources while improving work speed and quality. We have also pioneered the automation of consolidated delivery, which groups products by delivery destination—something we have done for over 70 years since our founding—to address the industry practice of sporadic ordering, reducing the labor required for consolidated delivery work to approximately one-fifth compared to Logis Daito (Daito City) and dramatically improving operational efficiency. Furthermore, leveraging our location in Higashiosaka, an area with one of the highest concentrations of small to medium-sized factories, we will implement joint transportation and delivery for our first time as a company, using our own trucks to transport cargo from other companies in the industry, achieving both lower transportation costs and lower CO2 emissions across the industry.

Highlights 03 YAMAZEN LOGISTICS CO., LTD. Becomes LOGIRISE CORPORATION

Group company YAMAZEN LOGISTICS CO., LTD. changed its name to LOGIRISE CORPORATION on April 1, 2025, and relocated its headquarters to the city of Higashiosaka. Since its establishment in 1993, YAMAZEN LOGISTICS has built logistics systems tailored to the product characteristics of both production equipment and consumer goods as a Yamazen Group company, conducting logistics operations through advanced information capabilities and a nationwide network. To make YAMAZEN LOGISTICS even more profitable going forward, we will build systems to handle not only inventory storage and delivery of Yamazen products but also warehouse operations and transportation/delivery operations from new shipping companies, such as manufacturers and machine tool trading companies within the industry. We will then aim to be a logistics partner that is of constant service and meets a variety of needs.

* Information as of April 2025.